About eco.flex

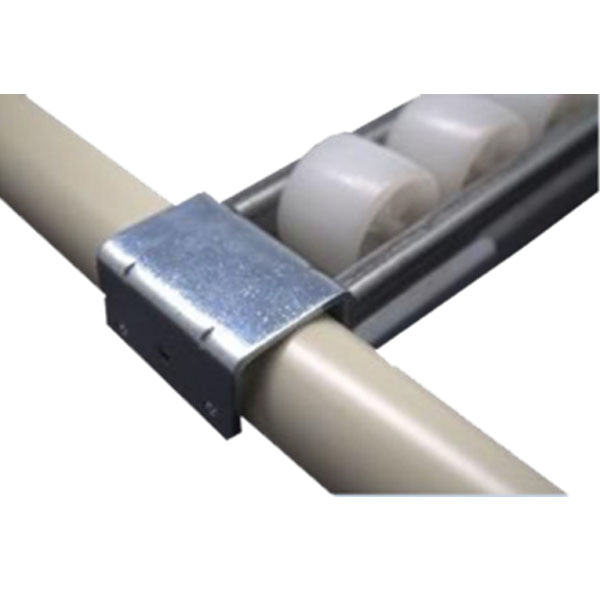

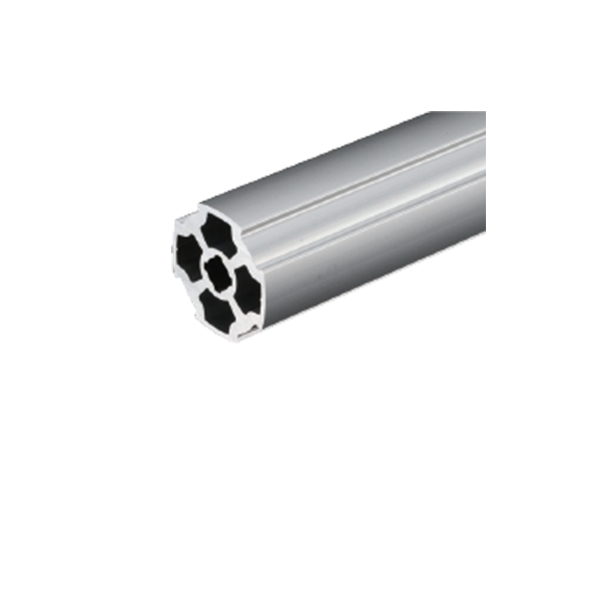

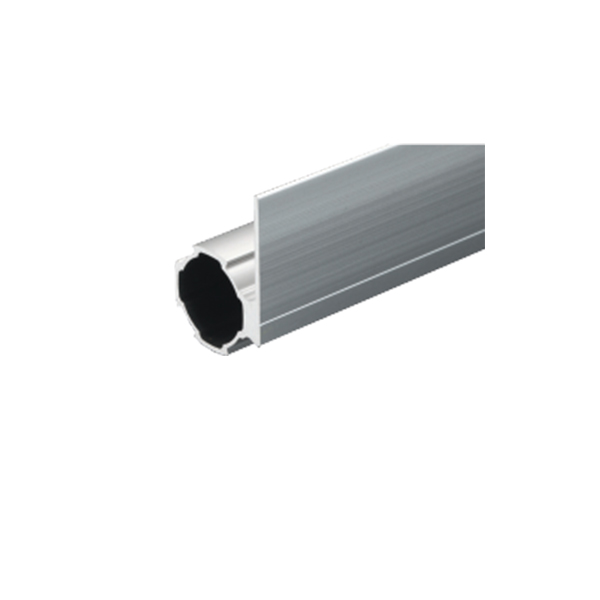

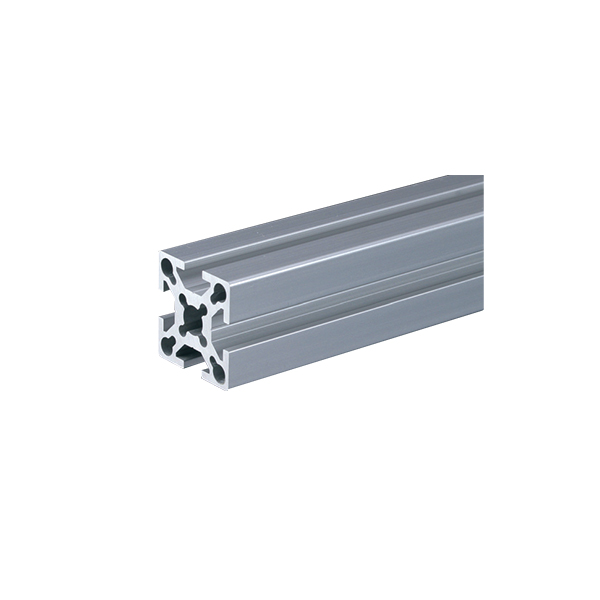

What is eco.flex ? (economic, ecological-friendly and flexible) is a modular system that consists of tubes/pipes, metal/plastic joints, roller tracks and accessories that can be configured and re-configured into material handling solutions for continuous improvement, kaizen and lean manufacturing.

Material handling and storage efficiency in manufacturing applications is enhanced by the superior customizability of a modular pipe and joint system. The tubes/pipes and joints can be configured in any way, to create simple material handling solutions.

Each application is unique and customized. Since eco.flex pipe and joint system requires only basic tools to assemble, anyone in your facility – from operators to maintenance to management can participate in making continuous improvement in your workplace. The simplicity of the eco.flex modular system makes it the perfect alternative to traditional bulky welded steel structures.

The modular eco.flex pipe and joint system enables rapid implementation and reconfiguration. New or temporary applications can be built quick and adapted easily to changing process requirements. The eco.flex pipe and joint system provides lower overall cost of implementation and ownership.

What are advantages of using eco.flex ?

1. Cost effective, as all the tubes/pipes and joints are re-usable

2. Versatile and flexible rack design

3. Space saving by customizing racks to fully utilize the floor space

4. Fast and easy assembly process

5. Rack systems can be easily re-constructed and modified

6. Clean and easy maintenance

HOW TO PURCHASE:

The eco.flex modular system can be purchased in 4 different ways:

1. Bulk Parts: Our entire product line (tubes/pipes, connectors, rollers, and accessories) can be purchased by the unit.

2. Kitted Structures (Self-Build): SPJS can provide pre-cut tubes/pipes and roller tracks, with the appropriate amount of joints and accessories; delivered in kit form as per your specifications.

3. Assembled Structures (Design and Build): SPJS will provide a finished assembled product from start to finish, including consultation, 3D design, and delivery to your specifications.

4. Design Service (Design and Self-Build): SPJS designers and technicians will develop your custom solution with 3D CAD software and determine the bill of materials required for your project.

For customers new to lean manufacturing and the eco.flex coated pipe and joint system, we also offer in-house assessments, as well as starter kits and training workshops to get your started. Please contact us for more information.