PIPE ท่อเคลือบ ABS

eco.flex

The standardized eco.flex pipes have a diameter of 28 mm. The pipe thickness for light and medium duty application is 0.7 mm and 1.0 mm. For heavy duty application, pipes with thickness of 2.0 mm are available. The eco.flex pipes consist of plastic coated, aluminum and stainless steel pipes.

Plastic Coated Pipe

The eco.flex plastic coated pipes are made of SPCC-B1 steel pipe coated with acrylonitrile butadiene styrene (ABS). The ABS coating provides the pipe with a nice finish as well as optimizes the strength of the pipe and the clamping force. ABS coating also prevents pipes from rusting and it provides excellent wear as well as impact resistance. The pipes are made available in different colours.

Key features of ABS coated pipes:

- Cost effective

- Durable and flexible

- Rust inhibitor applied to inner surface for extended lifetime cycle

- Adhesive coating between ABS and steel pipe to improve peeling

- Wide range of colour

- Available in ESD coating (black)

Colour chart of ABS pipes

IV

NB

SB

RE

BK

YE

GE

WH

LG

Wall thickness

| Wall thickness | 0.7 mm | 0.8 mm | 1.0 mm | 1.2 mm | 2.0 mm |

|---|---|---|---|---|---|

| Stainless Steel Pipe | ● | ● | |||

| ABS Coated Pipe | ● | ● | ● |

Wall thickness

| Type of Pipes | Stainless Steel Pipe | ABS Coated Pipe |

|---|---|---|

Standard Pipe  | ● | |

Slide Pipe  | ● | ● |

Stainless Steel Pipe

The eco.flex stainless steel (SUS) pipes are made of high grade austenitic stainless steel, which is nonmagnetic and strong corrosion resistance. Scratches on the surface will NOT lead to corrosion.

Key features of SUS pipes:

- Higher strength to weight ratio than that of coated pipe

- Superior resistance to oil and chemicals

- No burning during cutting

- Environmental friendly

- Electrostatic discharge, electrically and thermally conductive

- Best appearance over long term

Aluminum Pipe

The eco.flex aluminum pipes are made from aluminum extrusion materials with anodized treatment to enhance corrosion resistance.

Key features of aluminum pipes:

- Light weight. Density of aluminum is about 1/3 of steel density.

- Superior resistance to oil, chemicals and weather

- No burning during cutting

- Environmental friendly

- High reusability

- Electrostatic discharge, electrically and thermally conductive

- Best appearance over long term

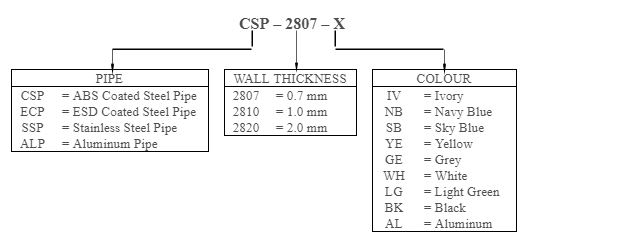

Coding system

Coding system

Unit of length : mm

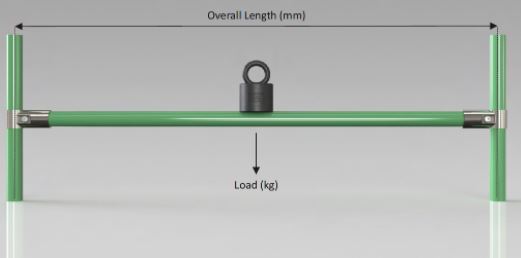

Pipe loading capacity

Pipe loading capacity

MAXIMUM LOAD LIMITS |

||||

|---|---|---|---|---|

| Pipe | Overall Length (mm) | Permanent Deformation (mm) | Total Bending (mm) | Load (kg) |

| CSP-2807 | 1000 | 0 | 13 | |

| CSP-2807 | 1000 | 5 | 24 | |

| CSP-2807 | 1000 | 10 | 32 | |

| CSP-2807 | 1000 | 15 | 40 | |

| CSP-2810 | 1000 | 0 | 14 | |

| CSP-2810 | 1000 | 5 | 25 | |

| CSP-2810 | 1000 | 10 | 32 | |

| CSP-2810 | 1000 | 15 | 38 | |

| CSP-2820 | 1000 | 0 | 12 | |

| CSP-2820 | 1000 | 5 | 18 | |

| CSP-2820 | 1000 | 10 | 25 | |

| CSP-2820 | 1000 | 15 | 30 | |

| SSP-2807 | 1000 | 0 | 11 | |

| SSP-2807 | 1000 | 5 | 17 | |

| SSP-2807 | 1000 | 10 | 24 | |

| SSP-2807 | 1000 | 15 | 30 | |

| SSP-2810 | 1000 | 0 | 12 | |

| SSP-2810 | 1000 | 5 | 18 | |

| SSP-2810 | 1000 | 10 | 24 | |

| SSP-2810 | 1000 | 15 | 28 | |

PIPE

Product type : Pipe Joint System