LS-DYNA ซอฟต์แวร์วิเคราะห์

Product type : Engineering Solutions

LS-DYNA® is a highly advanced general purpose nonlinear finite element program that is capable of simulating complex real-world problems. It is utilized by the automobile, aerospace, electrical, electronics, construction, military, manufacturing, and bioengineering industries to design and develop products.

Multi-Physics

Multi-Processing

Multi-Scale

Multiple Stages

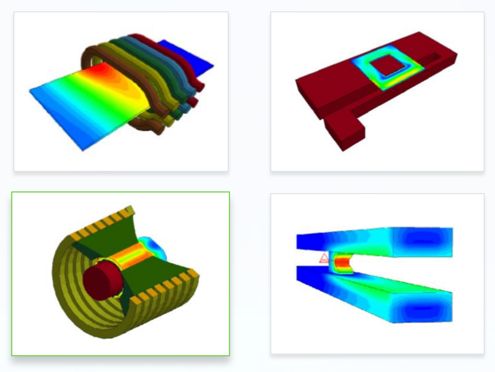

LS-DYNA is suitable to investigate phenomena involving large deformations, sophisticated material models and complex contact conditions for structural dynamics problems. LS-DYNA allows switching between explicit and different implicit time stepping schemes. Disparate disciplines, such as coupled thermal analyses, Computational Fluid Dynamics (CFD), fluidstructure interaction, etc.

LS-DYNA CAPABILITIES

- Nonlinear dynamics

- Parallel processing (SMP, MPP)

- Rigid body dynamics

- Quasi-static simulations

- Normal modes

- Linear statics

- Thermal analysis

- Fluid analysis (Euler, ALE)

- Failure analysis

- Underwater shock

- Crack propagation

- Real-time acoustics

- Earthquake ground motion

- Design optimization

- Implicit springback

- Multiphysics coupling (structural, thermal, fluid, acoustic, etc.)

- Structural-thermal coupling

- SPH (Smooth Particle Hydrodynamics)

- EFG (Element Free Galerkin)

- BEM (Boundary Element Method)

- Fully automated contact analysis

- Function input (FORTRAN or C syntax)

- Encryption of material input data

- Redundant network license server

- Electromagnetic simulation

LS-DYNA IN METAL FORMING

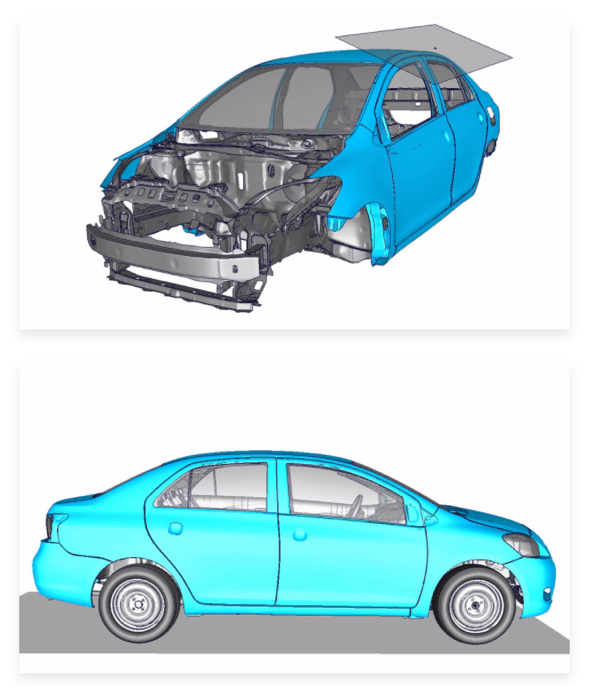

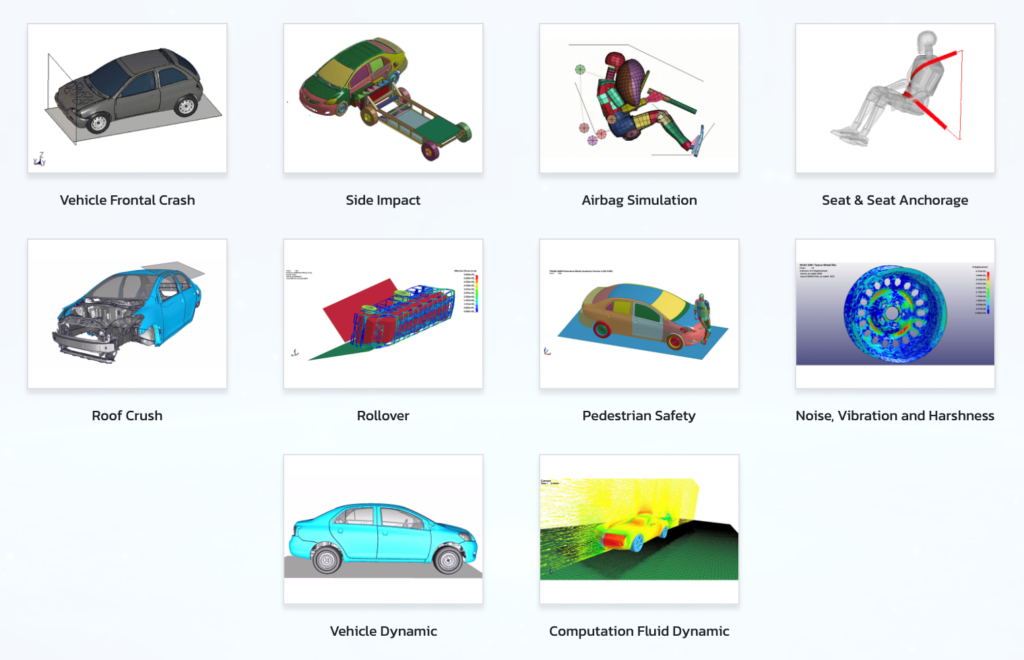

LS-DYNA® is widely used by the automotive industry to analyze vehicle designs. LS-DYNA® accurately predicts vehicle behaviour in a collision and the effects of the collision upon the occupants. With LS-DYNA®, automotive companies and their suppliers can test car designs without having to tool or experimentally test a prototype, thus saving time and expense.

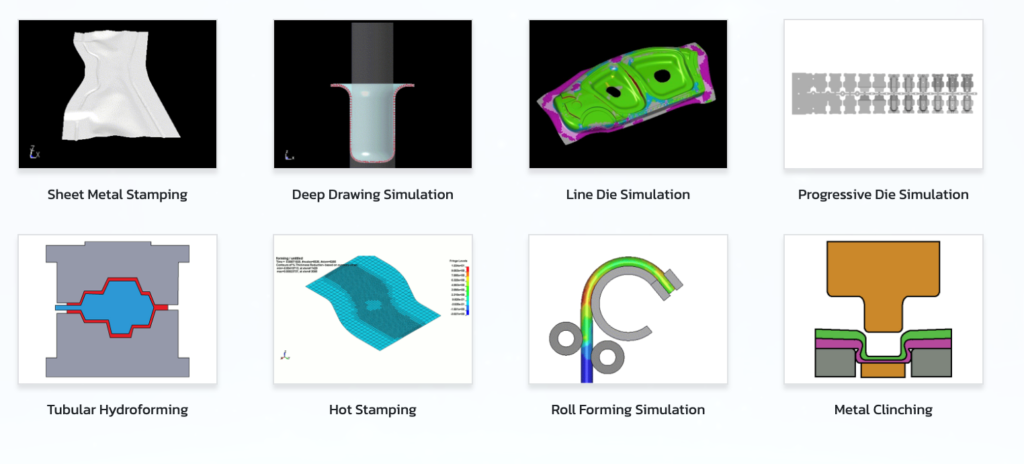

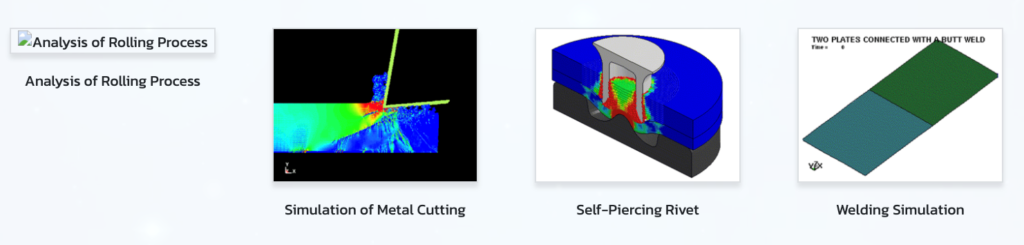

LS-DYNA IN METAL FORMING

One of LS-DYNA’s most widely used applications is metal forming. LS-DYNA® accurately predicts the stresses and deformation experienced by metal, and determines if the metal will fail. LS-DYNA® supports adaptive remeshing and will refine the mesh during the analysis, as necessary, to increase accuracy and save time.

LS-DYNA IN AEROSPACE

One of LS-DYNA’s most widely used applications is metal forming. LS-DYNA® accurately predicts the stresses and deformation experienced by metal, and determines if the metal will fail. LS-DYNA® supports adaptive remeshing and will refine the mesh during the analysis, as necessary, to increase accuracy and save time.

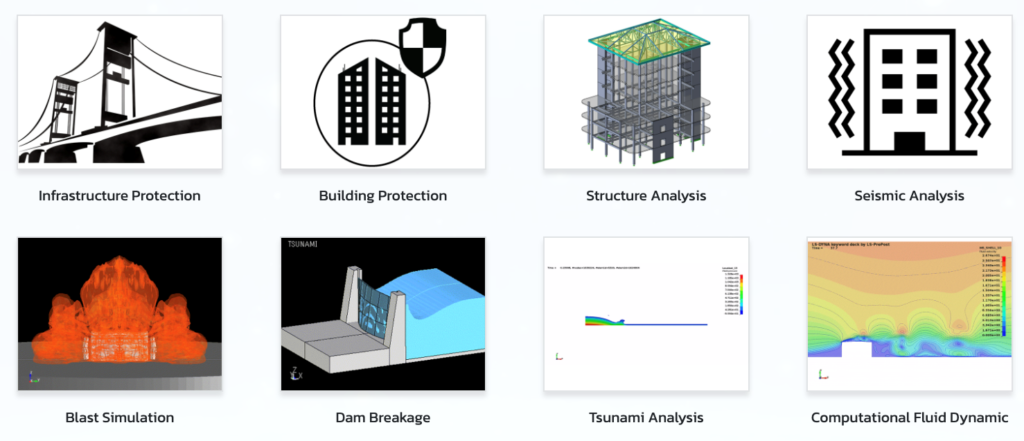

LS-DYNA IN CIVIL ENGINEERING

LS-DYNA® is widely used by the civil engineering to simulate structural failure.

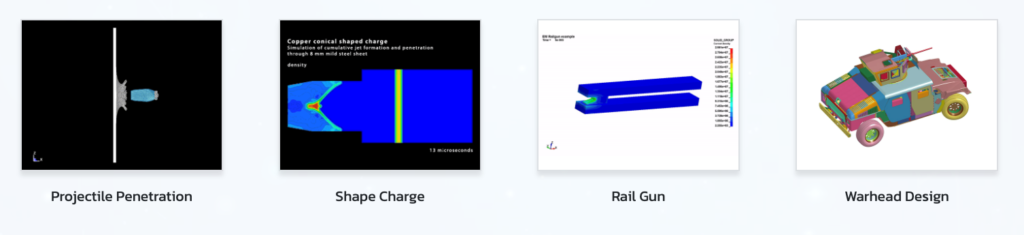

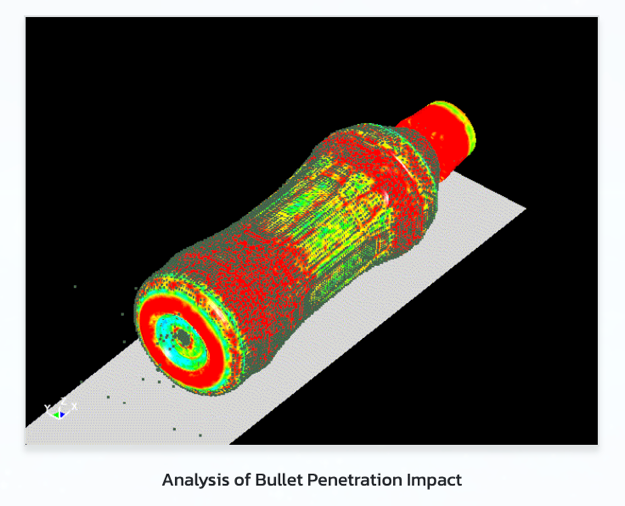

LS-DYNA IN DEFENSE

LS-DYNA® is widely used by the defense industry for weapon development.

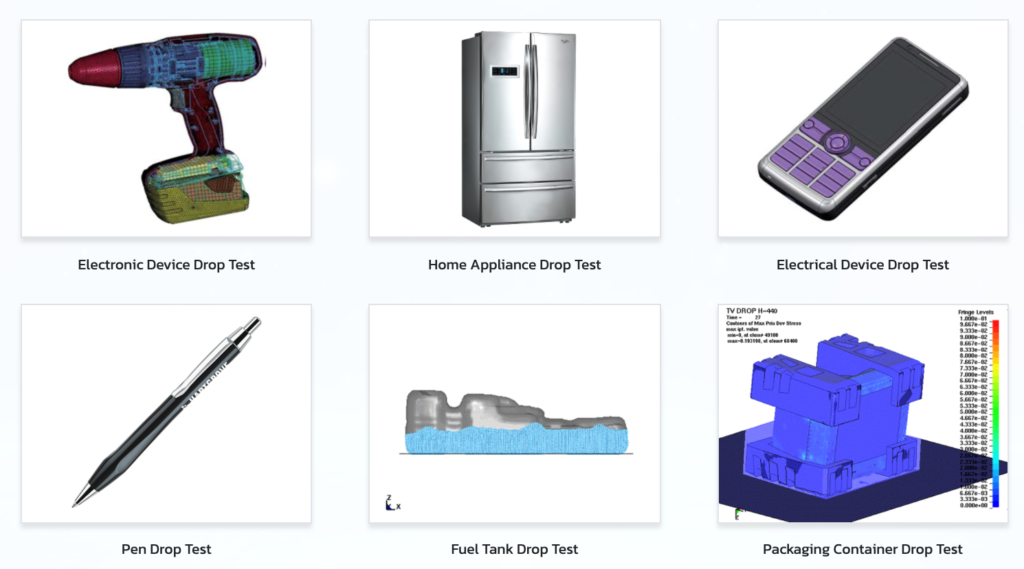

LS-DYNA FOR DROP TEST ANALYSIS

LS-DYNA is used to investigate the behavior of products under impact conditions due to dropping. The application range includes consumer products, tools and also container design. For example, in the field of packaging design LS-DYNA helps to develop food containers capable of sustaining dynamic loading conditions during transport and storage.

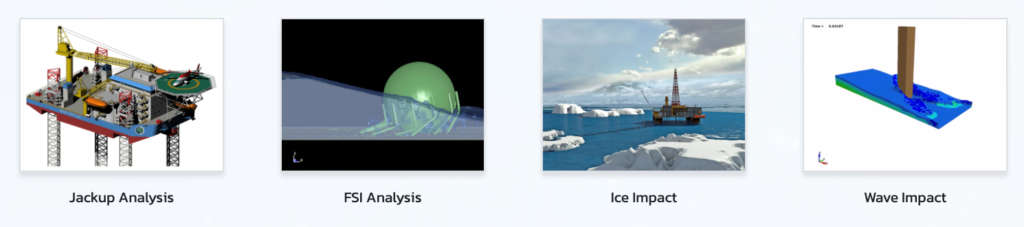

LS-DYNA FOR OIL & GAS

LS-DYNA® is widely used by the oil & gas industry.

LS-DYNA FOR CONTAINMENT

LS-DYNA acts as a tool to reduce risks of accidents that cause severe damage to communities or the environment by generating knowledge about how a system may fail. Thus, design changes can be made to reduce or even eliminate risks associated with the load cases considered.

For example, LS-DYNA is used to design the containers for transporting nuclear fuel elements. Thus, the container can remain closed and tightly sealed in the event of any foreseeable accident that may occur during transport.

Another example is the high-speed impact on objects, such as a turbine blade separated from the turbine may not cause harm to the embankment. The LS-DYNA enables the user to estimate the harm induced by the turbine blades that strike the turbine housing.

LS-DYNA FOR MANUFACTURING

The reliability and speed of production and packaging steps play a crucial role in determining the cost of the product in the commodity manufacturing industry. Fabrication processes generally involve nonlinear steps and use different physical effects. Its nonlinear capabilities and ability to couple different numerical schemes make LS-DYNA a unique tool for finding solutions to queries related to the layout of manufacturing processes.

For example, LS-DYNA can be utilized to investigate the deformation of a container during filling, handling, closure, packaging, and stacking. The performance of a snap fit after a series of opening and closings can be analysed as well as manufacturing tolerances and handling or transportation influences. Other applications may include folding tissues and packing bulk or granular goods.

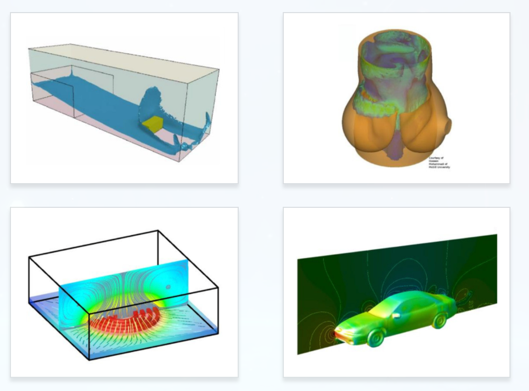

LS-DYNA FOR MULTIPHYSICS

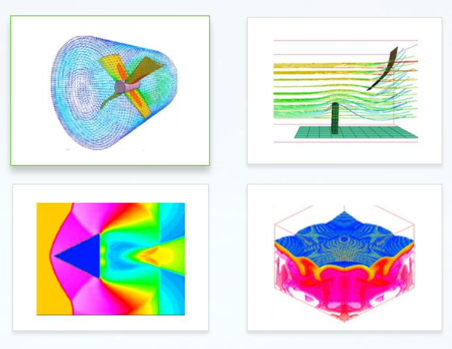

LS-DYNA includes three new solvers for Multiphysics purposes which are Incompressible Computational Fluid Dynamics solver (ICFD), Electromagnetism Solver (EM) and CESE Compressible CFD Solver.

NCOMPRESSIBLE CFD SOLVER

The ICFD solver can run as a stand-alone for pure CFD applications (the study of drag lift around bluff body and vehicles for example), or be coupled to the thermal and structural mechanical problems for linear and non-linear complex FSI and conjugate heat transfer applications.

Applications:

External aerodynamics for incompressible flows

Internal aerodynamics for incompressible flows

Sloshing, Slamming and Wave impacts

FSI problemsConjugate heat transfer problems

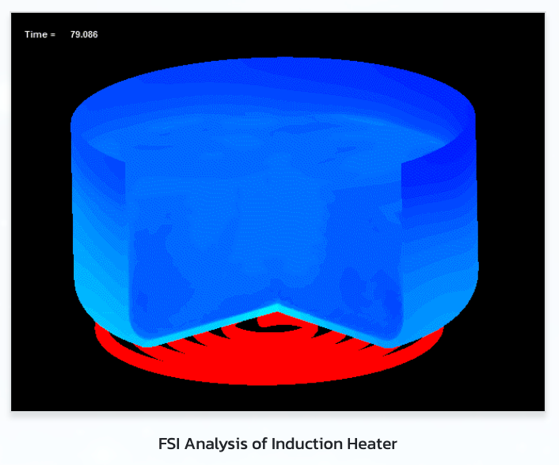

ELECTROMAGNETISM SOLVER

The EM module allows the introduction of a source of electrical current into solid conductors and the computation of the associated magnetic field, electric field, as well as induced currents. The main applications are magnetic metal forming or welding, induced heating, and so forth. The EM solver is coupled with the structural mechanics solver and the structural thermal solver.

Applications:

- Electromagnetic forming

- Electromagnetic welding

- Electromagnetic bending

- Inductive heating

- Resistive heating

- Rail-gun

- Ring expansions

CESE COMPRESSIBLE CFD SOLVER

The CESE solver is a compressible flow solver based upon the Conservation Element/Solution Element (CE/SE) method. It has many non-traditional features, including a unified treatment of space and time, the introduction of conservation element (CE) and solution element (SE), and a novel shock capturing strategy without using a Riemann solver. To date, this method has been used to solve many different types of flow problems, such as detonation waves, shock/acoustic wave interaction, cavitating flows, and chemical reaction flows.

Applications:

EShock wave capturing

Shock/acoustic wave interaction

Cavitating flows

Conjugate heat transfer problems

Different kinds of stochastic particle flows (dust, water, fuel, etc.)

Chemically reacting flows (detonating flow, supersonic combustion, etc.)

LS-DYNA FOR OTHER APPLICATIONS

Other LS-DYNA application:

- Can and shipping container design

- Electronic component design

- Glass forming

- Plastics, mold, and blow forming

- Biomedical Products

- Metal cutting

- Earthquake engineering

- Failure analysis

- Sports equipment (golf clubs, golf balls, baseball bats, helmets)

- Civil engineering (offshore platforms, pavement design)